Mapes Architectural Panels Fundamentals Explained

Table of ContentsThe Greatest Guide To Glazing Infill PanelsThe Basic Principles Of Mapes Insulated Panels The Lightweight In Fill Panels DiariesGlass Infill Panels For Stairs Fundamentals Explained

If modern look of standing joint steel roof is not precisely ideal for your home, after that you can go with metal roof shingles roofing that functions well for historic buildings, and provides the typical seek to your roofing.Whether you require Glazing Infill Panels, Spandrel Panels, Darkness Boxes, Soffits, Copings, Backpans or Flashings, Embury Company will provide promptly and also on spending plan. Allow our team aid and also guide you with all of you metal panel requirements. Our Cutting-edge Facilities enables us to function perfectly with any kind of sort of material as well as obtain you what you need.

The panels are available from.016 to 3/16 (.1875) of an inch, making use of Aluminum, Stainless-steel, Galvanized or ACM. Whatever the density, material or coating Emburite Panels will certainly respond to the demand.

The Curtain Wall design refers to mid-20th Century structures that use a premade outside wall sheathing system hung to their structures - mapes metal panels. Making use of such innovation dates back to the 1918 Hallidie Structure in San Francisco, which is attributed as the very first building to make use of an all glass exterior wall system.

The initial major example of the design was the Equitable Financial Savings & Loan Structure in Portland, Oregon carried out by designer Pietro Belluschi in 1948. As the world's first completely enclosed air-conditioned structure, this smooth 12-story structure rapidly set the pattern for lots of post-WWII high-rises and also tiny scale workplace structures. The drape wall system is included a repeated grid of vertical extruded light weight aluminum mullions and also horizontal rails.

10 Simple Techniques For Infill Panels For Windows

These spandrel panels can come in a variety of materials. Early spandrel panels were constructed from heat-strengthened opaque glass integrated with tinted ceramic. The Pittsburg Plate Glass Company made the glass panels under the brand name "Spandrelite," and also provided 8 conventional shades. The Libbey-Owens-Ford Company marketed sixteen colors options under the "Vitrolux" brand.

Thought about ideal for essentially any kind of dimension commercial, federal government or institutional structure, the Drape Wall design came to be extensive by the early 1950s. Several post-WWII structures of differing designs likewise integrated drape wall systems right into some exteriors however are not considered Drape Wall surface design unless most of the noticeable exteriors are so created (in fill panels).

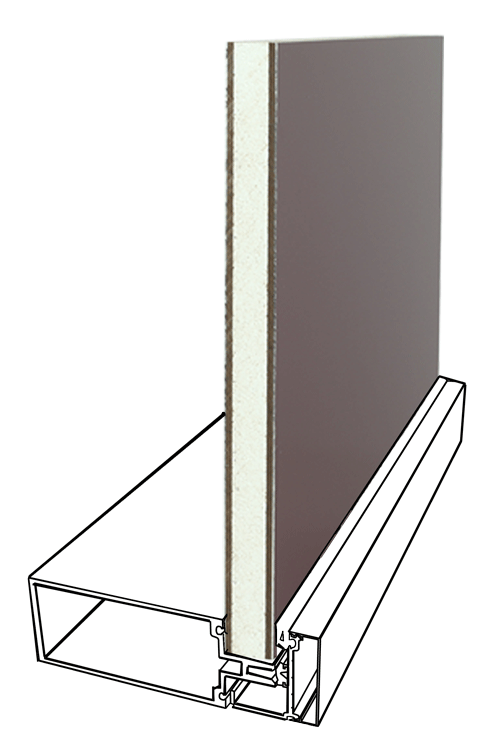

Curtain wall surface and also store front glazing systems are typically a thin, non-structural outer faade component of a building that can span numerous floorings or be integrated right into a punched opening. Polishing systems function mainly as air and water vapor obstacles, resisting air or water infiltration and also suit building and also system activity caused by wind, thermal, and seismic pressures.

As such, light-weight materials can be used in their advancement. Industrial glazing systems are usually created of aluminum-framed wall surfaces with glass, steel panels, louvers, operable home windows or vents, or stone veneer infills. Building envelope specialists will certainly usually suggest developers on curtain wall surface as well as shop demands for building movement, thermal expansion and also contraction, water diversion, as well as thermal performance.

Opaque glazing, metal panels, MCM (steel composite products) panels, or insulated laminated panels are normally utilized as spandrel infill. When insulation is used inboard of the spandrel infill, an air area is consistently presented to prevent thermal damage to the spandrel infill. Unfortunately, the air space can give a possibility for condensation to form on the indoor face of the spandrel infill.

The Best Strategy To Use For Infill Panels For Windows

Need to inadequately developed spandrel conditions be left neglected, condensation can lead to spandrel panel ceiling wetness or visual damage to the spandrel panel and/or interior surfaces. When condensation types at the spandrel infill of a glazing system, several sorts of damages can occur, and also the effects of condensation can be significant. Along with wetness damages and microbial growth, condensation growth on spandrel infill can additionally have an adverse result.

One way to postpone the formation of condensation on the glazing system spandrel infill is to utilize the building HEATING AND COOLING system. By increasing air movement near these places, even more warmth will be transferred to the assembly as well as boost interior surface temperatures. An additional method to make use of the HVAC system is by lowering the interior relative humidity established factors with respect to outside temperature.

The 8-Second Trick For Glass Infill Panels

Along with integrating recovery methodology, methods to lessen condensation possibility throughout design include: Commonly drape wall systems have greater resistance to condensation than shop systems. Making use of drape wall is one method to reduce, or postpone the start of condensation formation. At Pie, we provide 2-D thermal modeling (THERM) to help our customers with the style of spandrel locations.

By knowing surface area temperature levels, Pie is able to establish under which conditions condensation will certainly occur, along with identify change points at which condensation will certainly not establish, making it much easier to forecast and also remediate (in fill panels). Furthermore, various configurations can be modeled to maximize indoor surface area temperatures. Setting up back pans into the spandrel infill glazing pocket, which are vented to the outside with insulation outboard of the pan, advertises raised interior surface temperature levels with the included advantage of reducing warm transfer through the spandrel infill.