Not known Facts About Infill Panel

Table of ContentsInfill Panel Fundamentals ExplainedA Biased View of Infill PanelThe 9-Second Trick For Infill Panel

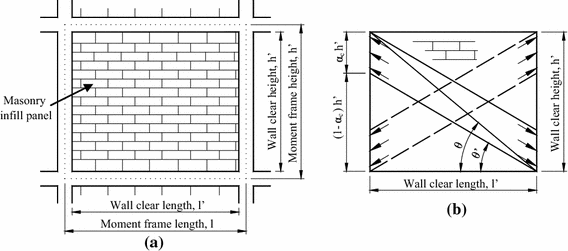

This is often crucial in repair applications where the top quality of the original flooring building is not sufficient to withstand hefty loads. Light steel external wallssupport lightweight cladding by fixing directly through the insulation to the supporting C areas or indirectly to straight rails that are fixed to the C areas. Masonry cladding (brickwork )is fairly heavy and should be ground-supported for walls approximately 12m high. For taller walls, it should

be supported by the main frame using stainless steel angles connected to the edge light beams. It is tied back to the infill wall surfaces utilizing upright channels in which the wall surface ties lie. In healthcare facilities, institutions as well as other similar applications, light steel infill walls as well as dividing walls have important advantages by being re-locatable as demand for area adjustments during the life of the structure. infill panel. Steel is non-combustible unlike timber

The Greatest Guide To Infill Panel

( satisfying BS EN 520, Type F). Light steel walls can achieve outstanding acoustic insulation of 60 d, B +when making use of dual layers of plasterboard as well as insulating patchwork between the studs. A high degree of thermal insulation is offered by a range of foam insulation boards that attach externally to the studs to develop a' warm framework '. @ & & h2 @ [leading] Efficiency requirements for infill wall surfaces @&&/h2@ The efficiency needs for external walls using light steel parts include thermal, acoustic, fire resistance, weather-tightness issues as well as wind resistance, each of which are explained in the adhering to areas. SCI has actually published ED017 on infill walling as well as also a collection of Technical InfoSheets, one of which got on infill walling ED013. Various other magazines can be discovered on the internet site of the Light Steel Forum. @&&h3@ [leading] Thermal efficiency @&&/h3@ They are assessed separately to the U value of the cladding or roofing and also are qualified by a' psi 'worth. This is an action of the additional warmth shed due to thermal linking as a direct or factor value that is included to the basic efficiency of the building envelope. For light steel infill wall surfaces, thermal linking can take place at the flooring slab and also at the columns where they go across the line of the wall surface. Nonetheless, the quantity of thermal linking is reasonably reduced where the insulation passes outside the edge of the flooring piece. Thermal linking ought to

preferably not add greater than 20 %to the total warm loss through the structure envelope.

The Ultimate Guide To Infill Panel

Actual air seepage rates under normal conditions are just about 5% of the test value, depending upon the dimension of the structureand also its use. For highlysealed structures, such as laboratories, fresh air high quality need to be preserved by appropriate ventilation of cleansed air. Condensation is a sensation where warm damp air condenses on chilly surface areas. This result is minimised by ensuring that cold spots on the inner surface of the structure are within restrictions( usually 10 % of the temperature of theremainder of the wall surface). Where there is the original source a risk of condensation within the cladding itself, a vapour limited membrane layer might be positioned on the within the building. by utilizing audio protecting boards instead basic wall surface board or by enhancing the number of layers. For external wall surfaces and compartment walls, Authorized Paper B (England) mentions that the appropriate period of fire resistance relies on the use, elevation and also size of the building. Where there is a risk that failing of the outside wall surface might lead to terminate infect adjoining structures( a border problem ), the wall surface needs to please fire resistance requirements; this may affect the type of cladding that can be made use of. In such case, a brickwork exterior fallen leave that is laterally sustained by the light steel infill wall surface might be preferred. Materials pop over to this web-site attaining limited combustibility can not be considered to fulfill the need utilizing a different category approach. Amended guideline 7( 3 )offers an exception for sure elements located in outside wall surfaces as well as defined add-ons. Interpretations of external walls and also specified add-ons have been added as well as these definitions consist of any kind of components of the external wall surface as well as specific accessories to the exterior wall (porches, photovoltaic panels as well as sunlight shading ). An Assessment document was generated on the recommended changes to the Structure Laws as well as the alterations to Component B exist in a file qualified' Changes to the Accepted Papers', December 2018 The main effects for assistance on infill walls for structures of even more than 6 storeys is that insulation systems that do not please the above requirement are not permitted. @&&h3@ [top] Weather condition resistance @&&/h3@ 12 onwards in Authorized Record C. The exposure of external walls to wind driven rainfall is also based on the geographic area that is identified as having' protected' to' really severe'exposure click for more info in accordance with BS 8104. Numerous components of the UK autumn under the' modest' or' serious' exposure areas. Table 4 of Approved Record C provides the minimal size of tooth cavity for the various exposure areas and also cladding materials. infill panel. BS 5628-3 describes the aspects influencing rainfall

penetration in dental caries walls. For curtain walling systems, the kinds of building are specified in BS EN 13830. The Centre for Home Window as well as Cladding Technology( CWCT) has actually additionally generated guidance on weather-tightness and also linked full-scale screening routines for these light-weight built-up cladding systems, which may consist of some light steel supporting parts. Windows existing the greatest risk of water infiltration as well as the following information for insulated make demonstrate how to manage water ingress. Advice on the use as well as detailing of protected make cladding affixed to light steel infill wall surfaces is given up SCI P343. The efficiency may be boosted by usage of proprietary window sheaths which fit snugly around the home window, as revealed below. Normal information of protected cladding at a window Window covering information made use of with insulated render. @&&h3@ [leading] Wind resistance @&&/h3@ @&&h2@ [

leading] Cladding systems as well as user interfaces @&&/h2@